Everybody and their brother has some sort of DIY or build pictures of their keezer collar, so I’m not going to focus on the standard part of the build.

Difficulty:

This project just requires some basic building skills, but you might need some help getting the keezer onto the Bierwagen.

Time Required:

About an afternoon, more for painting and how you wish to finish it.

Posts for this Project:

Part 1: Introduction

Part 2: Building of the frame

Part 3: Bicycle wheel attachment

Part 4: Getting the keezer onto the Bierwagen

Part 5: Keezer collar (this post)

Part 6: Storage of the Bierwagen

Affiliate Links

Overview:

Since my collar will only get used once a year, or at least not a permanent addition to my keezer, it just needed to be easily removed and disassembled.

Construction:

Going in, I knew that it would not be permanently assembled, so I did not use wood glue at the joints or caulk in the corners. Yes, it is fairly inefficient to not seal it, but it stays cool just fine when it needs to.

I used 2×6 wood to create the border frame, but added some 2×4 posts that protrude down into the keezer interior to keep it from falling off.

I drilled the 3 holes with a wood boring bit. I got one many years ago for finishing our basement and I’ve gotten lots of use out of it. When using my corded hammer drill, it just rips right through wood. In my opinion, they work much better than standard hole saws. It may not leave as clean of a hole, but since the edges will be covered by the collar on the beer shank, I’m not to worried.

I used some large fender washers for the inside so that the nuts had a good solid surface to snug up against. If you just snugged up to the wood, they most likely won’t tighten all the way and will pull into the wood.

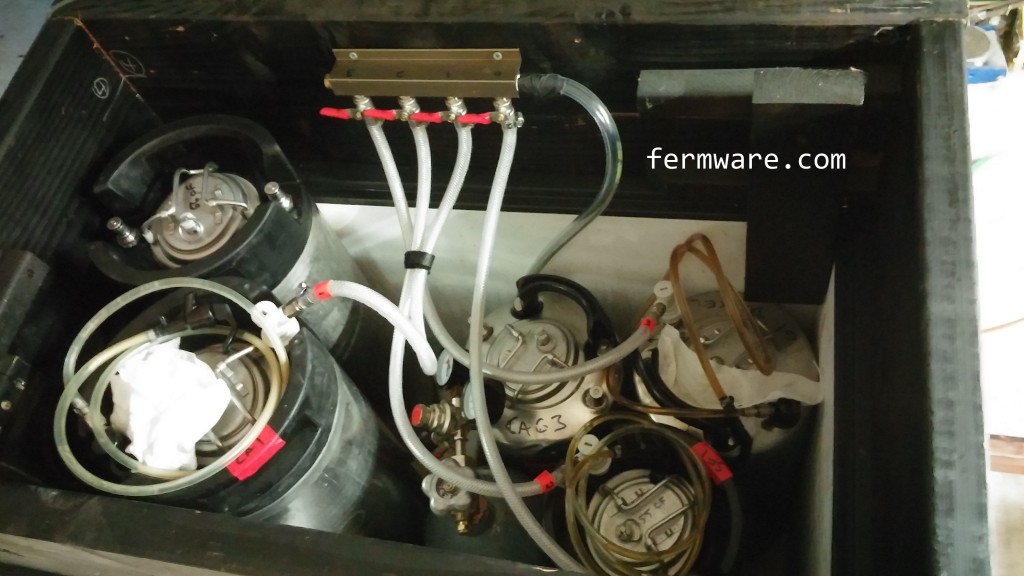

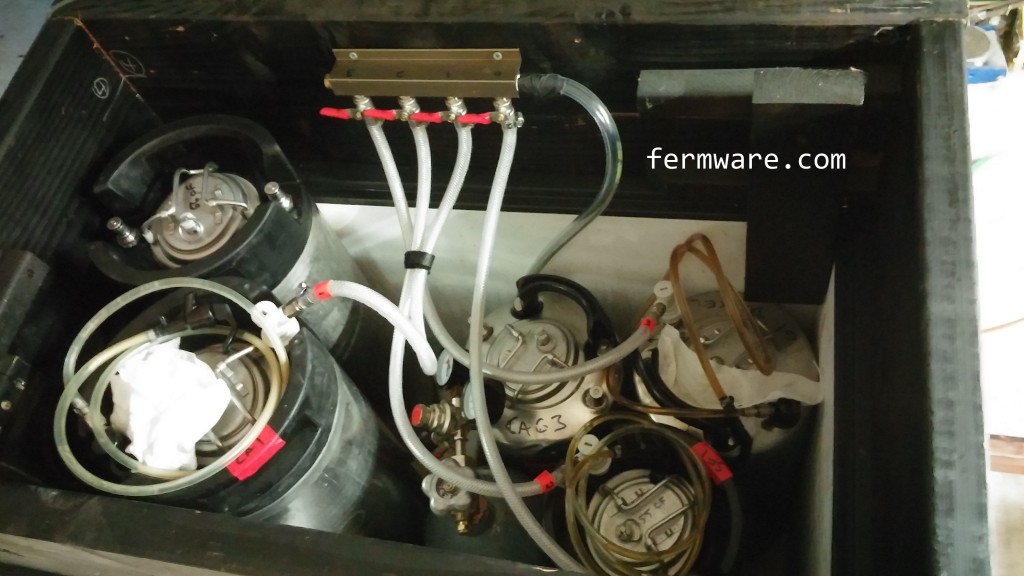

Keg arrangement and interior:

Here is how I arrange the kegs in the keezer. I’ll actually have 6 kegs at our party this year, so I’ll have to unceremoniously carry an extra keg from the garage fridge to the backyard.

I still need to desperately add a circulation fan to the interior. I’ve got the fan, but have not yet mounted it.

Nothing novel here, I just used more deck screws to lightly hold the manifold to the back wall of the keezer.

Signage

Not only did I make tap handles for each beer, but I thought it would be nice to add some descriptions for each beer on tap and laminate them. Most of our friends are now accustomed to “craft beer”, but I thought a little extra info couldn’t hurt. You can see on this picture, the velcro strips I put on the collar to hold the signs up. Yes, they are in different positions. It is just my 2012 to 2013 changes in position for the signs.

And the signs in action

Here are my signs by the way.

The Strausstoberfest is the house offering

The Dunkel Side was a favorite last year

Catcher in the Rye was my Rye PA, but will be replaced by a lower ABV Cream Ale at the party this year

Temp Controller

I then mounted my Ranco controller on the back and remounted the hinges onto the collar. I did not use the screws that were used on the freezer itself, but rather some longer sheet metal screws that held just fine in the wood.

Disassembly and storage:

Here is my method, which may serve as a guide for how you store yours (if you don’t make it permanent). Disassemble the collar whichever way you need to.

I then actually just ended up using the exact same screws that held the collar together to attach them to the interior wall of my garage. It’s actually behind where I store my keezer, so it’s not in the way and plus by attaching them to the wall, it keeps them up off the ground.

Up next…

How to store the Bierwagen (if you don’t have tons of room)