Difficulty:

If you are even a novice woodworker, this should be a piece of cake. Actual work time was probably about 15 minutes. Gathering materials and your tools will add whatever time it generally takes you.

Affiliate Links

Supplies Needed:

- 48″ section of shelving

- 11″ to 12″ is a typical depth

- I used a melamine board, because I had it on hand, but any shelving material should do

- Scrap strip of wood for some supports

- Again, I had a piece that was 3/4″ x 3/4″, but I’ll let you decide

- something on the order of 40″-44″ should be close enough

- Wood or drywall screws

- They need to be shorter than the stackup of your shelf and wood strip (you’ll see later what I mean)

Tools Needed:

- Drill

- I’ve got a Makita drill and driver kit that is used in 95% of any of my projects. If you don’t have a set, you need to. Bosch, Makita and DeWalt all make good stuff. A drill is, well, a drill. But I love the impact drivers. They make it effortless to run screws into anything.

- Tape measure

- Circular Saw

- Clamps (for securing the wood to your work surface when cutting)

The Build:

Alright, lets get to it. Measure twice, cut once. Right??

You should have the interior dimensions of the locker in hand. Many schools provide this information on their website. Ours were 13-1/2″ wide, by 11″ deep. I went just a bit under on width at 13-3/8″. You don’t want too much free play however, because if there is too much movement, the shelf could collapse on itself. You’ll know how sturdy it is when you install it in the locker. The 11″ standard shelf depth worked out well, but I still had to trim a little off due to the frame of the door.

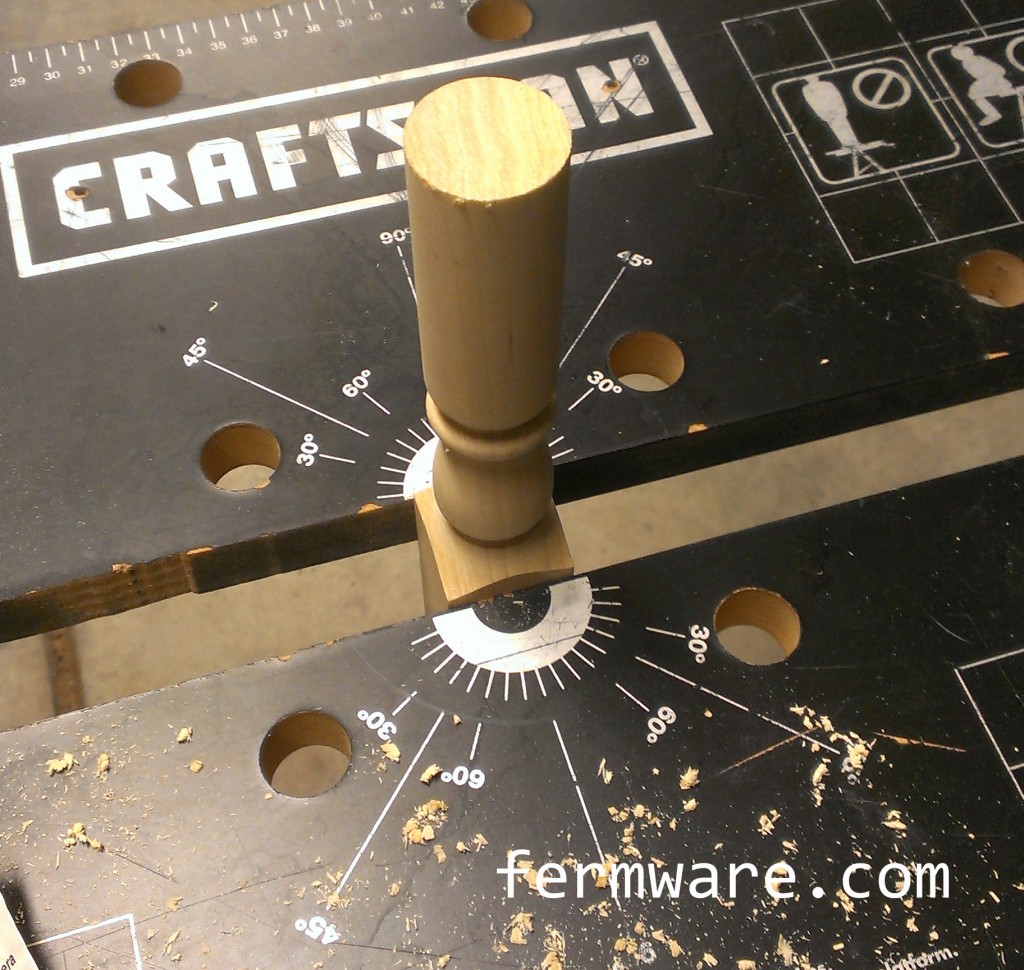

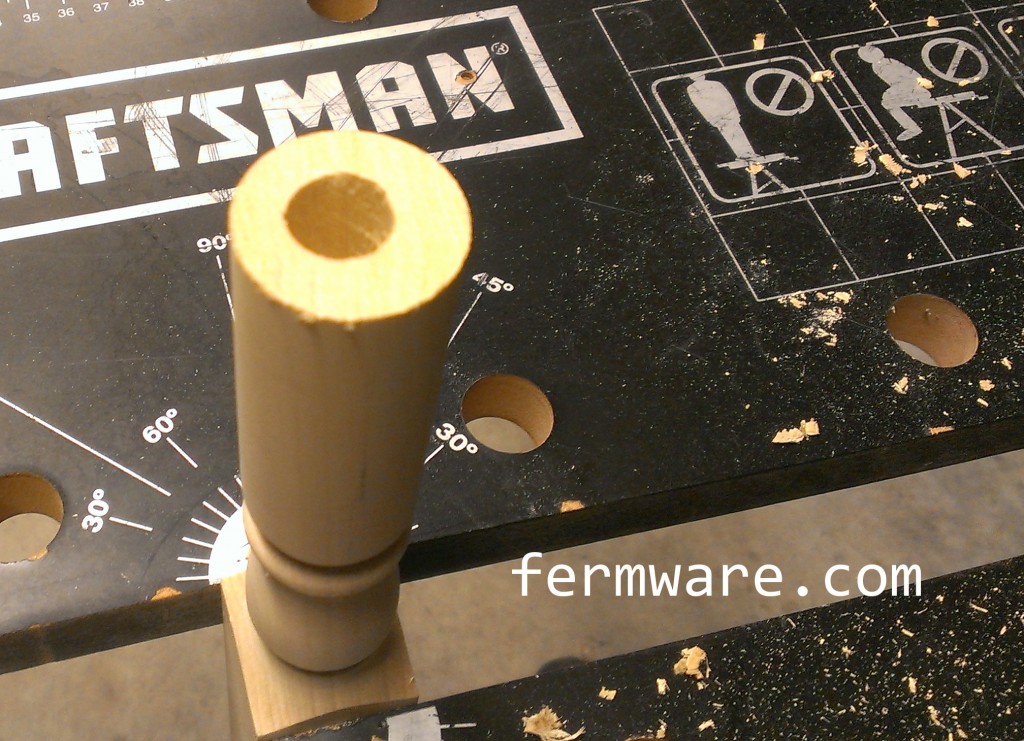

To help you visualize how this is going to go together, here is what each corner will look like. You can see that the uprights support the weight of the shelf. Then the stops that are screwed to the shelf basically prevent the uprights from leaning in. The interior wall of the locker prevents the uprights from falling out. Easy right?

Cut the top shelf piece to length.

Then decide how tall you want it. If you got a 48″ section, you should have enough wood to make something around 16″ tall at the most. That should be sufficient for most books and notebooks. Remember your total height will be the length of each upright, plus the thickness of the shelf. And the underneath height will be the length of the uprights.

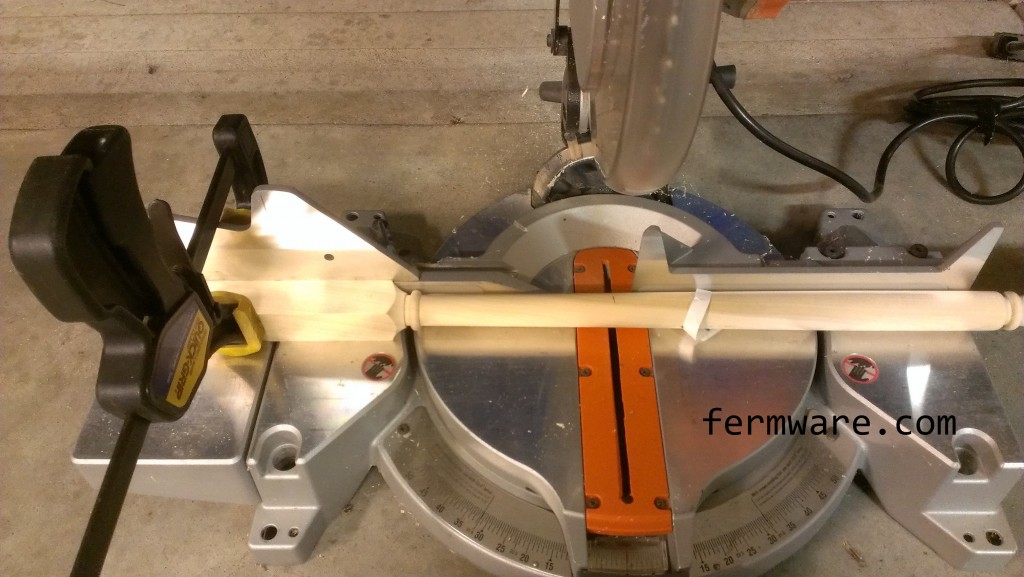

Now cut the uprights, just as you did for the top.

Next will be the strips that keep the uprights from moving. These should be shorter than the depth of the shelf. They will be fastened to the shelf top with screws. You’ll need two strips per shelf. I’m building two shelves here (one for each daughter needing one), hence a total of 4.

Mark out a line approximately 1″ from each end and then eyeballing the center should be good enough.

Pre-drill vs. Through Hole

You’ll want to drill “through holes” in the strips and “pre-drill” the shelf.

A through hole is just that, it allows the fastener to go through a material without actually gripping it and is larger than the major (or maximum) diameter of the fastener.

A pre-drill is used to reduce the risk of the wood splitting when you drive the screw in. An appropriate pre-drill size for wood is right at the minor diameter or slightly under. You can measure these dimensions if you have a pair of calipers, but I’m using my “eyechrometer” for these.

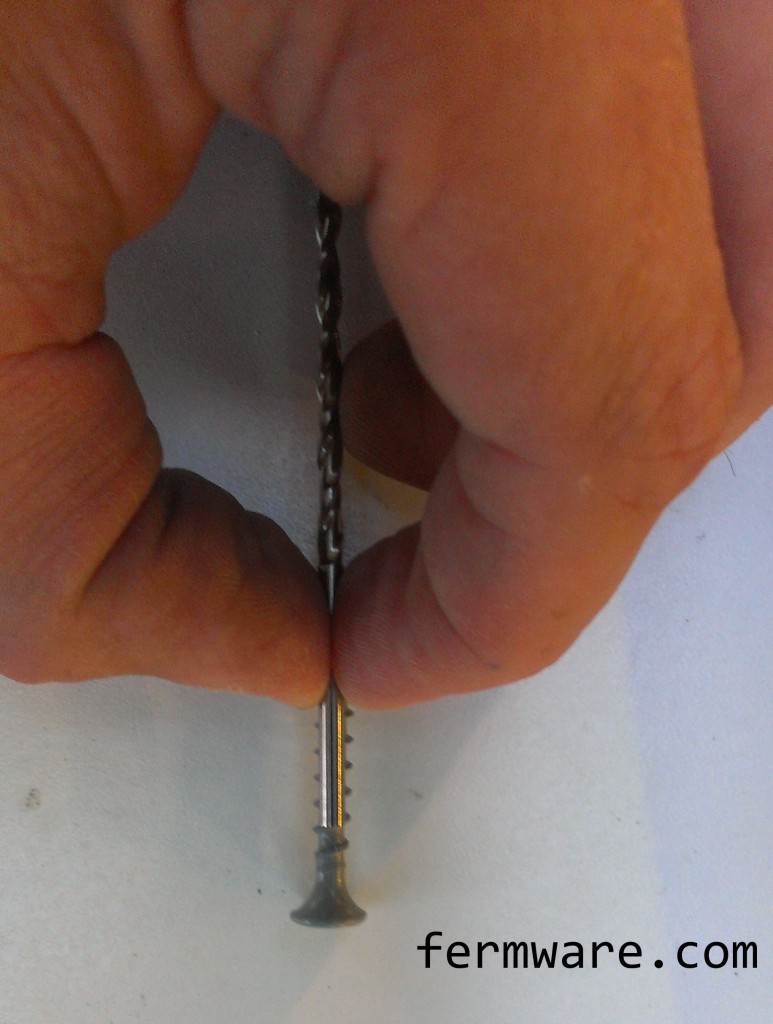

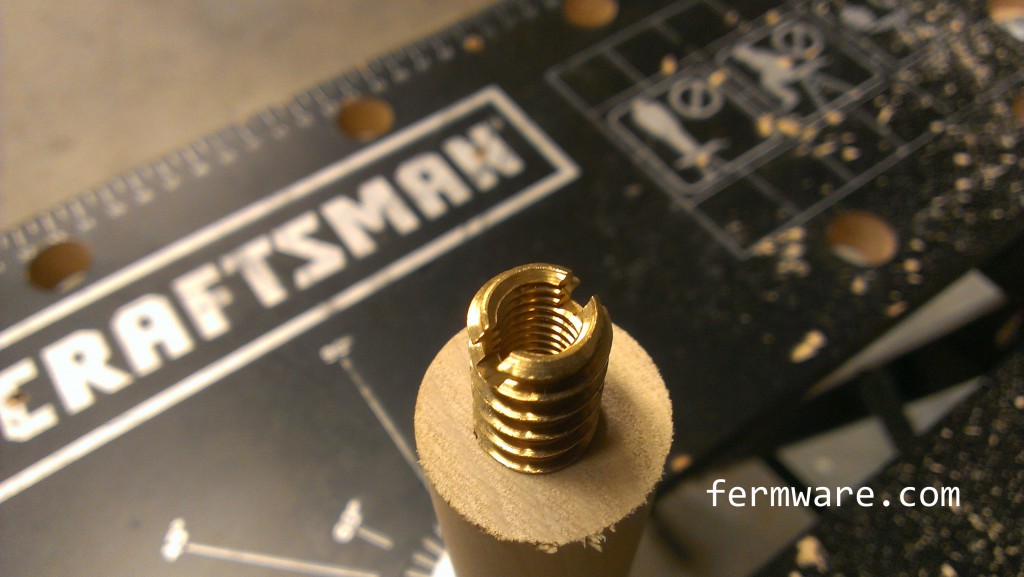

You can see below that the drill bit is slightly larger than the screw. This is what I will use to drill the through holes in the wood support strips.

This next image shows selecting the pre-drill size for the shelf. Notice that the drill diameter is approximately the same as the root diameter of the screw.

This next step is optional. I used a counter-sink kit to allow the screws to sit flush with the top of the wood when fully secured. Sometimes in harder woods, you’d end up splitting the wood if you ran the screws hard enough into the wood to make them flush. They basically create a cone shape for the head of the fastener to sit in.

See, nice pretty countersunk holes.

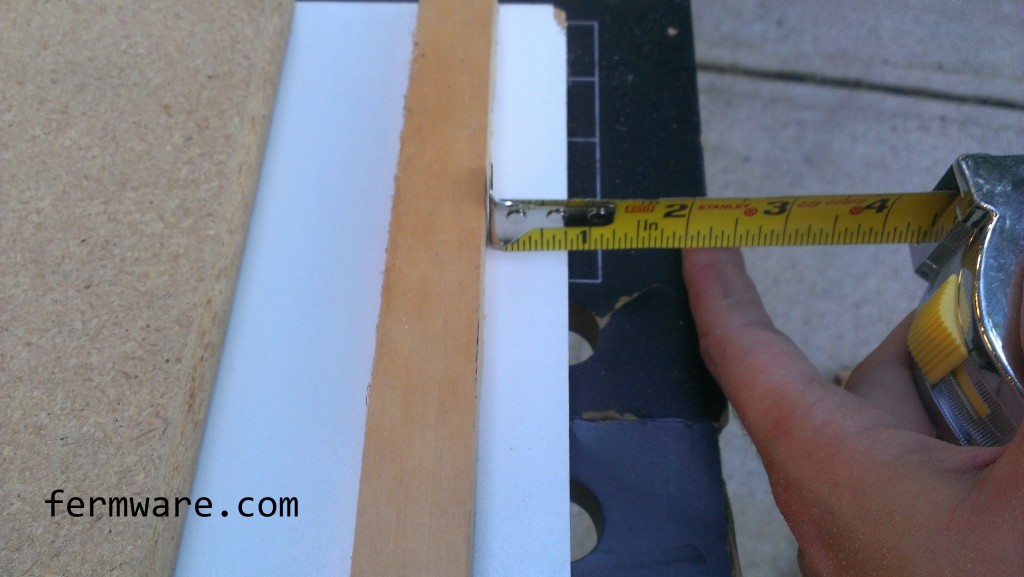

Now we need to pre-drill the shelf to attach the support strips. You’ll need to measure the thickness of your upright.

Then use that measurement to determine the spacing from the edge of the shelf to the location of the support strip.

Mark a line so you know if anything moves when you are drilling the holes.

You’ll need screws that are shorter than the thickness of the shelf and the support strips.

You’ll also want to be careful to not drill all the way through the shelf. Pointy screws poking out tend to rip books and cut hands! I’ll sometimes use a short section of masking tape wrapped around the drill bit to mark the proper depth of the drill bit.

Now take your pre-drill size and use the holes in the support strips as a location guide.

Once you have everything pre-drilled, it’s time to secure them to the shelf. Nice and flush!

Here is the completed shelf sitting up against the screwed together version 1 from last school year.

Besides getting it to the locker, you’re DONE!

Getting it into the locker:

- Set the uprights on the sides of the locker floor

- Place the shelf on top, ensuring that the support strips fit in between the uprights

Not into brewing, but like to make stuff? Check out these posts:

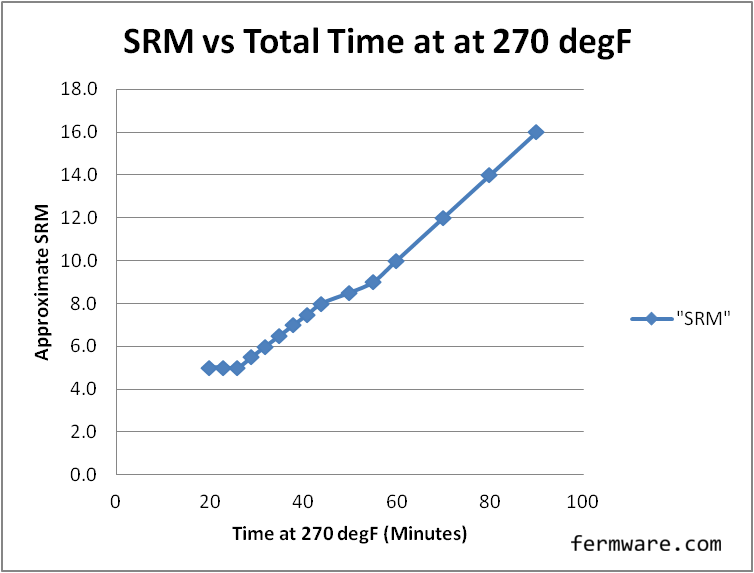

Making Belgian Candi Sugar

Rolling Deep Freezer Dolly