Difficulty:

This project requires a few inexpensive special tools, but will most likely take an entire weekend, lots of improvisation, some thorough cleaning and the cost of the fridge takes it to level 4.

Affiliate Links

Cost:

It all depends on what materials, tools and fridge cost is, but I would peg the average cost of this project at about $200 (including a second hand fridge). I scored a fridge on Craigslist for $100. The value for the fridge size I got is typically between $100-150.

Disclaimer / Caution:

If you are using a new-ish refrigerator, just keep in mind that we’ll be permanently be modifying it, so if there is any existing warranty, it will most certainly be voided by this project.

Posts for this Project:

Part 1: Introduction (This post)

Part 2: Clean up

Part 3: Disassembly

Part 4: Door modification

Part 5: Shelf building

Part 6: Finishing up and other observations

Introduction to this project:

This will be my 5th conversion of a refrigeration appliance into a fermentation support device. I started with my keezer, then converted two dorm fridges, followed by Lagerator III. The last one was taken over by my wife for her cake decorating business Tiffany Takes the Cake. Since I didn’t want to share the cake fridge with my fermenting lagers due to the potential of the cakes absorbing the sulfer odor of fermentation and the fact that I needed to manage the fermentation of seven 5-gallon batches of lager for our Strausstoberfest party, the need arose for yet another…

My initial pipe dream goal was to pull the guts from a cheap fridge and then fit them into a custom built cabinet meant to house many fermentation buckets, corny’s and anything you want to keep cool.

Time and the fact that I realized I could do it another way, convinced me to just find an ideal fridge on Craigslist and tear out the divider between the freezer and the fridge. I also modified the doors to be one large full length door.

As this project sits currently, I can fit seven standard fermentation buckets in there at the same time, or the bottom shelf area is tall enough for a full size keg, corny’s and my large-ish 20# CO2 bottle with the regulator attached.

In this multi-part post, I’ll show you how my build went.

I also have not yet advanced the project to my ultimate goal of two separate temperature zones and some sort of BrewPi/remotely monitored and controlled setup. For now, it’s just a single chamber with one of my homebuilt Arduino based temperature controllers.

Tools Required (or to make the job easier):

I would recommend that any serious DIY’er has every single one of the tools recommended for this project. They are some of my most used tools.

- hacksaw

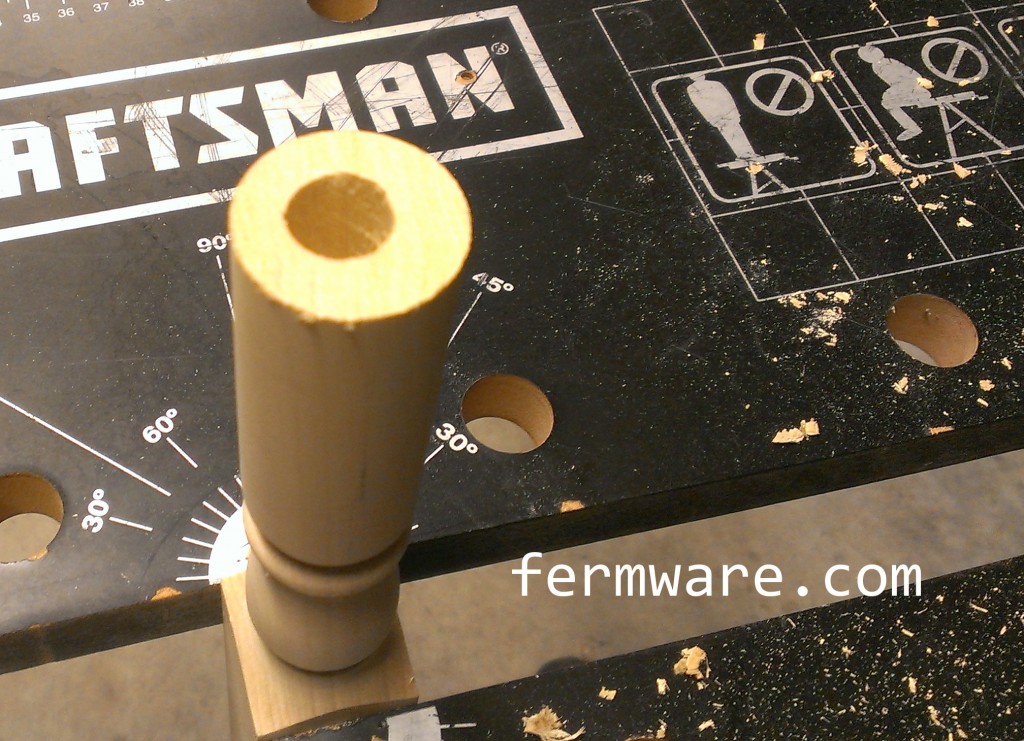

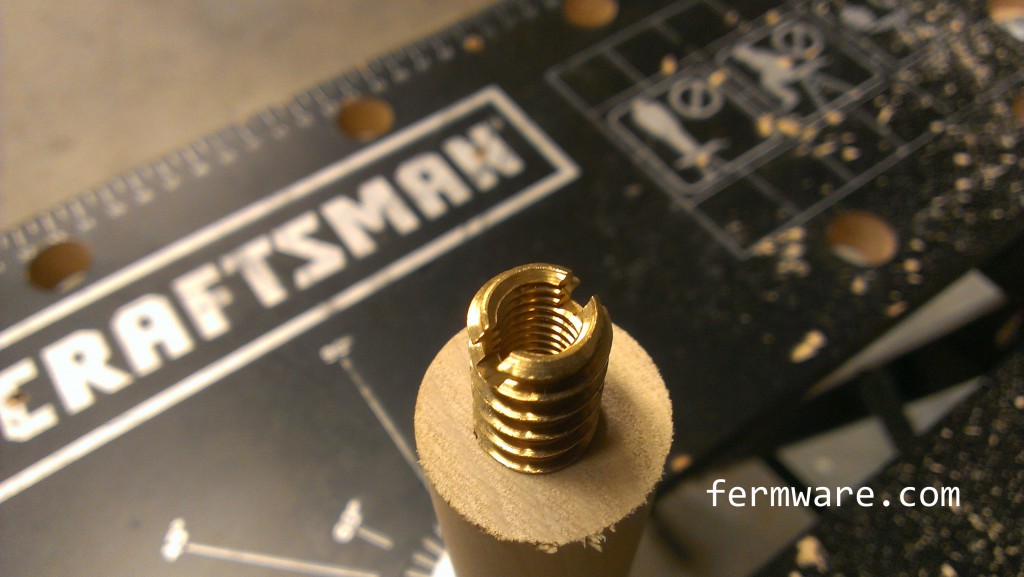

- set of assorted drill bits

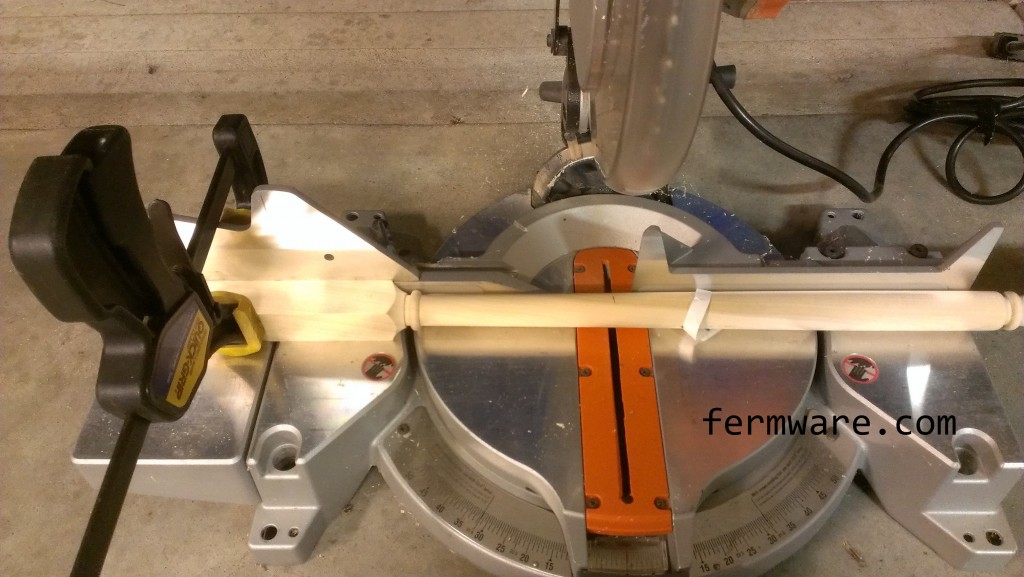

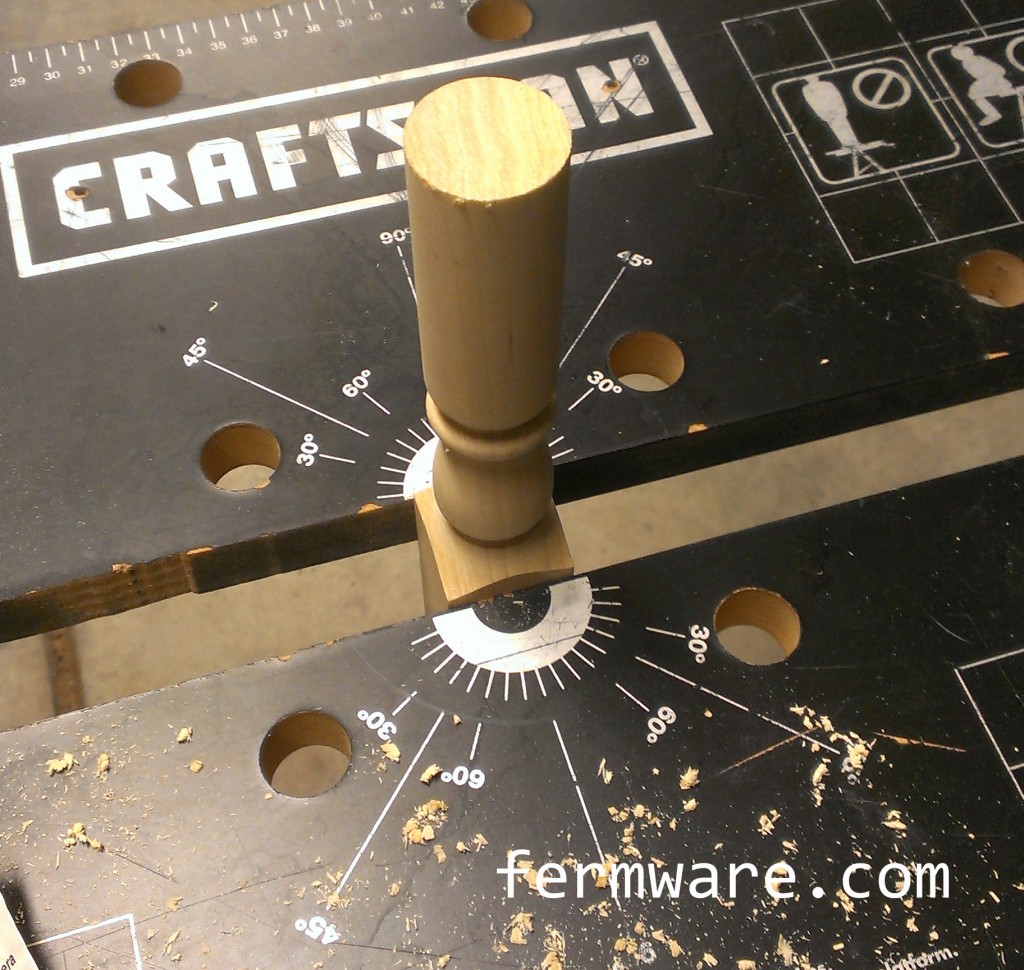

- miter saw

- circular saw

- handheld jig saw

- hand drill

Less common, but equally important and useful tools:

A set of assorted screw, torx, hex, socket and screwdriver bits (all refrigerators are different). The set shown above is the exact set i have and it’s served me well (cars, refrigerators, toys, electronics, etc…)

Tin Snips

If you don’t have a pair already, go ahead and get a set of three. I was being cheap and only got one, but they some in sets of three that are optimized for cutting on different sides of material (left, right and center). They are extremely useful. In this project you’ll use them to cut the FRP board and the aluminum. They are made for cutting sheet metal, but I end up finding many uses for them.

Tack puller

I actually got this many years ago during a summer job prepping refrigerators for delivery. I can’t tell you how many times I’ve found a use for this little tool. This is a must in any handymans arsonal.

- Pulling small nails out where a hammer would be cumbersome

- Pulls staples out of the floor when converting from carpet to laminate or tile

- Getting stubborn rivets out of holes

- Pulling plugs out of holes

- Trim pieces on cars

- The list goes on…..

File set

Again another worthwhile purchase that you’ll use over and over. In this project they are used to clean up the cuts in the aluminum angle.

Magnetic Bowl

Also called “dog dishes” or “dog bowls”. For some reason, I hadn’t ever seen these until I worked in racing. I’ve got several in different shapes and sizes. They are durable metal bowls with a strong padded magnet on the bottom. The magnet serves two purposes. One, to keep steel fasteners contained in the bowl. Two, to serve as an attachment method to metal work surfaces. I get lots of use out of mine. If Ralphie’s Dad had one of these when changing the tire in A Christmas Story, he never would have gotten in trouble for saying “Ohhhhhh, Fuuuuddddggge!” These have saved me many times from chasing screws all over the garage and under shelves.

Nut Setter

I can’t even remember where I obtained this, but they come in different sizes and have a magnet in the tip to hold on to screws. Why they insist on calling them “nut” setters is beyond me. This will be used to drive sheet metal screws into the fridge and most likely will be the hex size for most fasteners in the fridge.

Supplies Needed:

- 2×4 lumber to create support for shelves

- Drywall screws (lots of them)

- Plywood of your preference (I happened to have 1/2″ sitting around in just the size I needed)

- Stain or some kind of waterproof sealant for the wood

duct tape : MacGyver :: 2×4’s and drywall screws : Me

FRP Board (approx $25 for a 4’x8′ sheet)

If you can find plain plastic sheet, fine. I just chose this because it seemed ideal for this project. It’s easy to clean up and the textured surface has less resistance when sliding my fermenting buckets around in the fridge. It’s just fiberglass and resin, so it won’t mold or mildew. This will be used to replace the inner surface of the doors as well as the covering for the shelf.

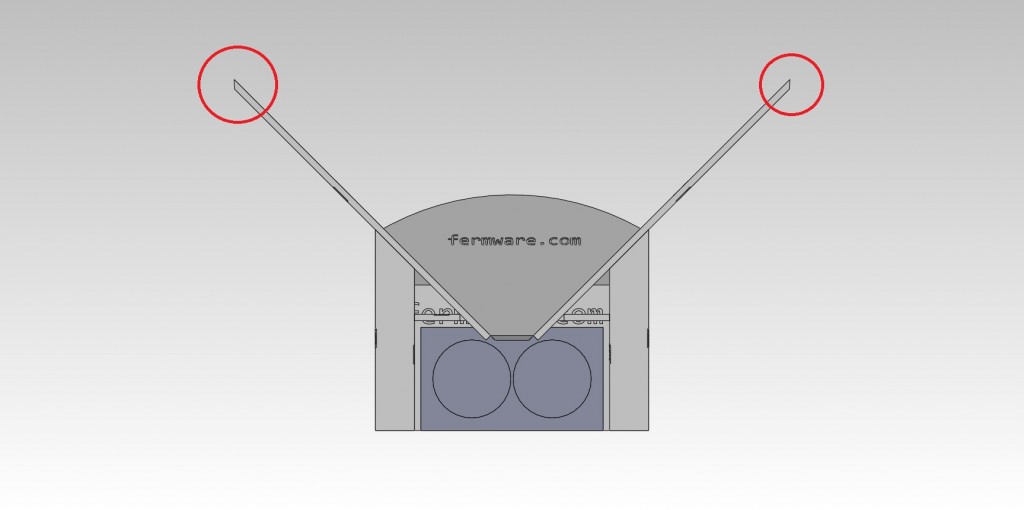

Aluminum Angle

You don’t have to get the exact size I purchased, but this happened to work out perfectly for my doors. I used this to connect the freezer door to the refrigerator door and make one giant door.

Sheet Metal Screws

These will be used to secure the aluminum angle to the doors to make a one piece door.

Wire Shelving

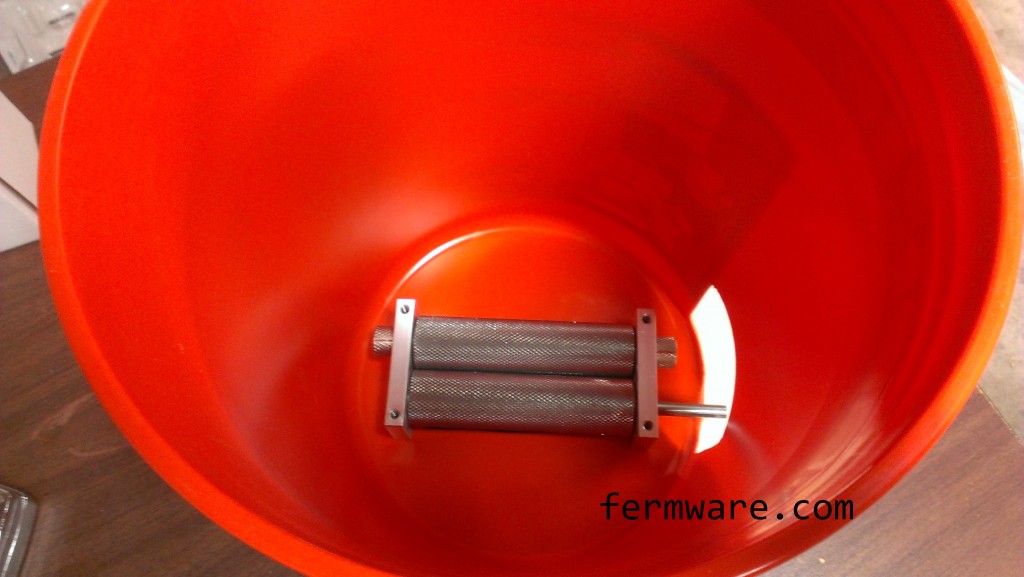

I used this on the previous lagering fridge (now used for cakes). It’s lasted over a year with no signs of rust. They are painted or have a thin rubberized coating, so they shoudn’t rust unless you scratch the covering off or possibly on the ends where you cut it. The piece I used was actually the other half of the full span shelving I used to make said prior lagering fridge.

Acetone

You should have this around your garage anyway. It’s great to remove sharpie from glass or metal. It is a prime (if not sole) component of nail polish remover. It’s not lung or skin friendly, so make sure you wear gloves. In this project, you’ll use it to remove your sharpie markings from the FRP board where you cut. But be forewarned, acetone has a tendency to melt many kinds of plastic, so move quickly.

Nitrile Gloves

I use these all the time. The link in the title is to the ones I purchase all the time from Harbor Freight. They are a good value and are fairly durable. I prefer the blue gloves, simply because when you do get grease and dirt on your gloves, you can tell and know not to touch anything clean. Use these in this project when cleaning the fridge as well as when you are using the acetone. I also prefer nitrile over latex, because with the latex gloves you are left with hands smelling like balloons. Plus some people have or develop latex allergies.

Up next…

Posts for this Project:

Part 1: Introduction (This post)

Part 2: Clean up

Part 3: Disassembly

Part 4: Door modification

Part 5: Shelf building

Part 6: Finishing up and other observations